RC-Baustelle.de (http://www.rc-baustelle.de/index.php)

- Modelle (http://www.rc-baustelle.de/board.php?boardid=5)

-- Bagger (http://www.rc-baustelle.de/board.php?boardid=6)

--- [1:14,5] CAT 320D excavator (http://www.rc-baustelle.de/thread.php?threadid=4267)

Geschrieben von caterpilar am 04.10.2012 um 18:58:

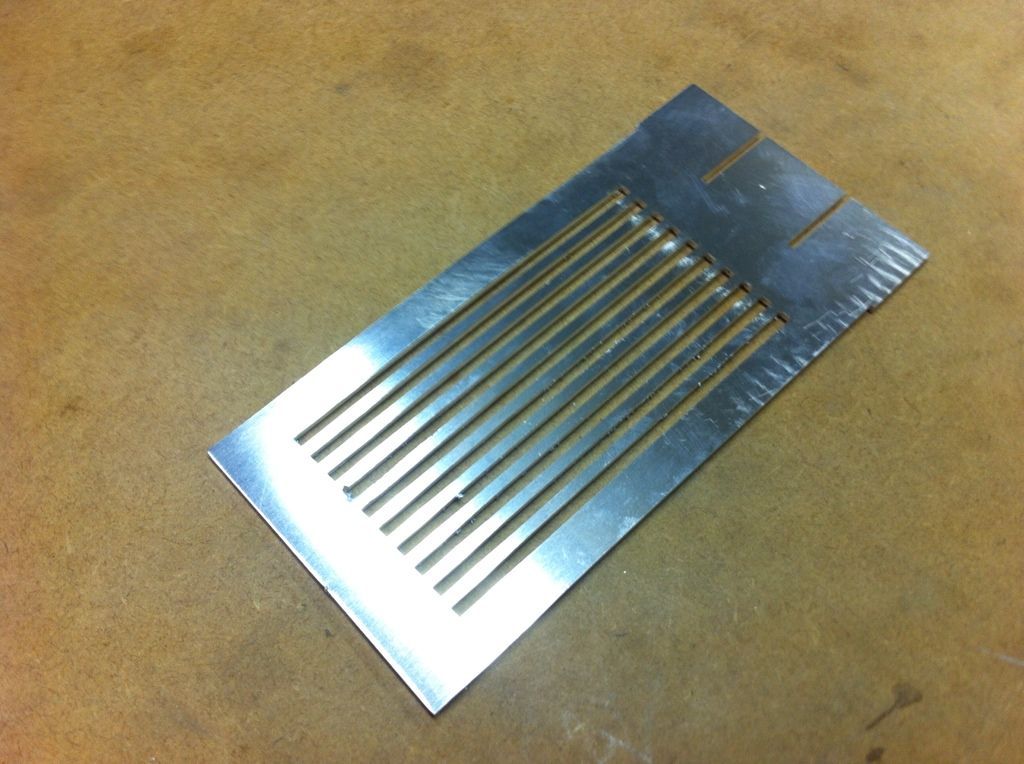

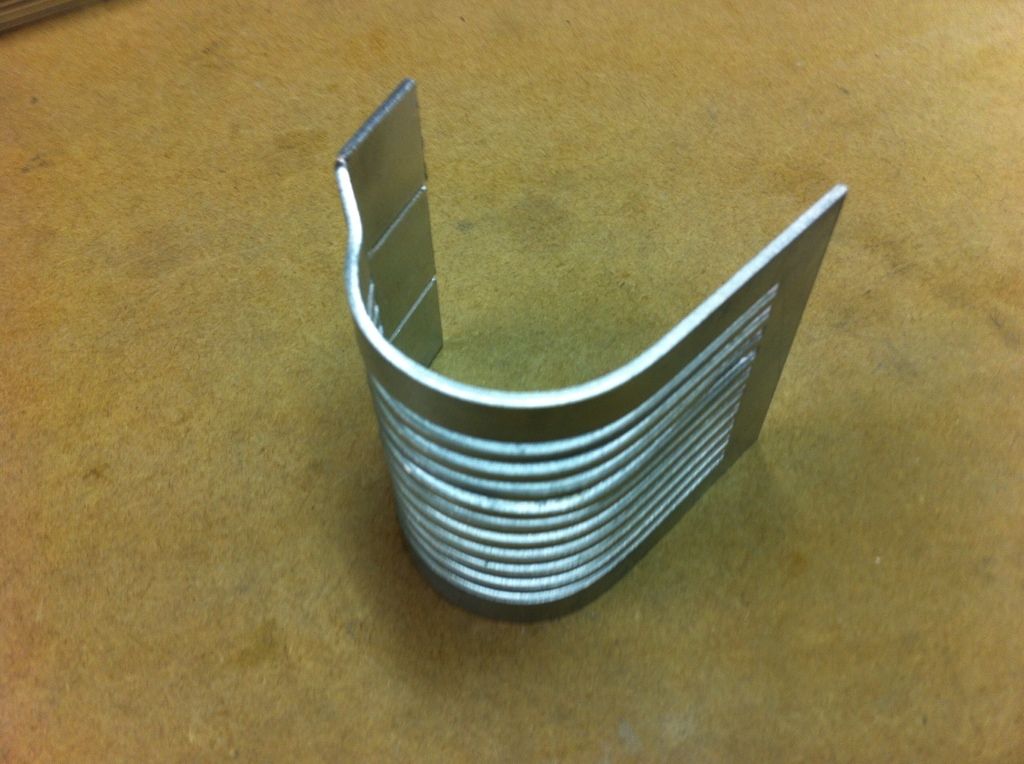

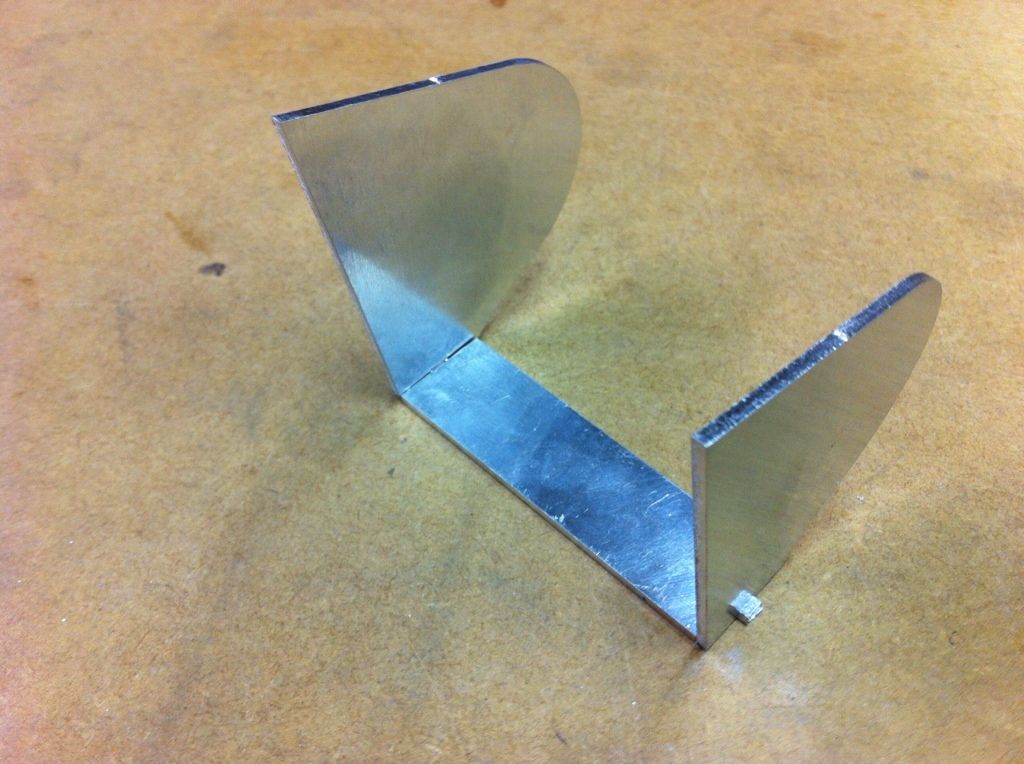

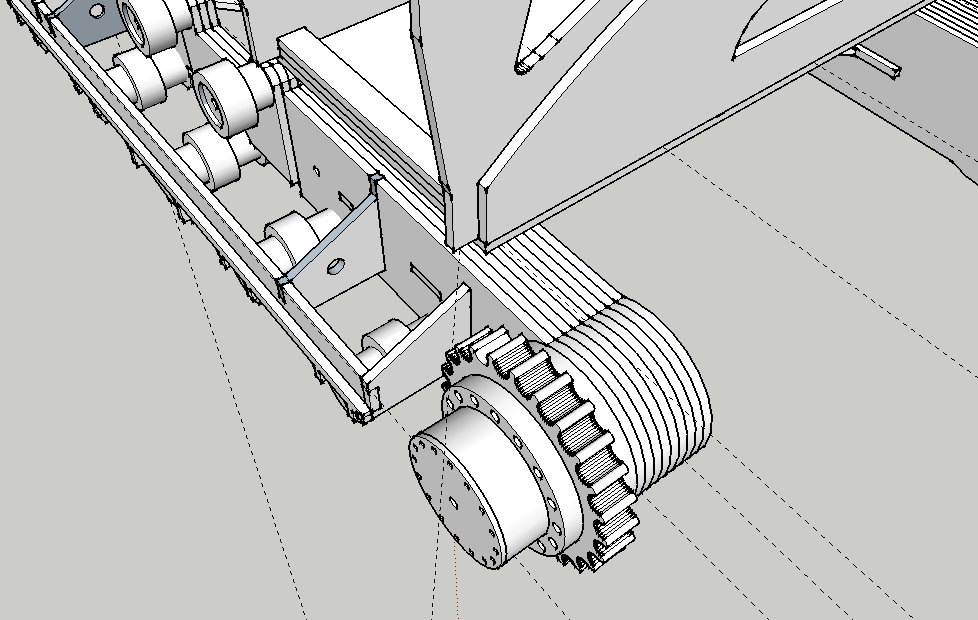

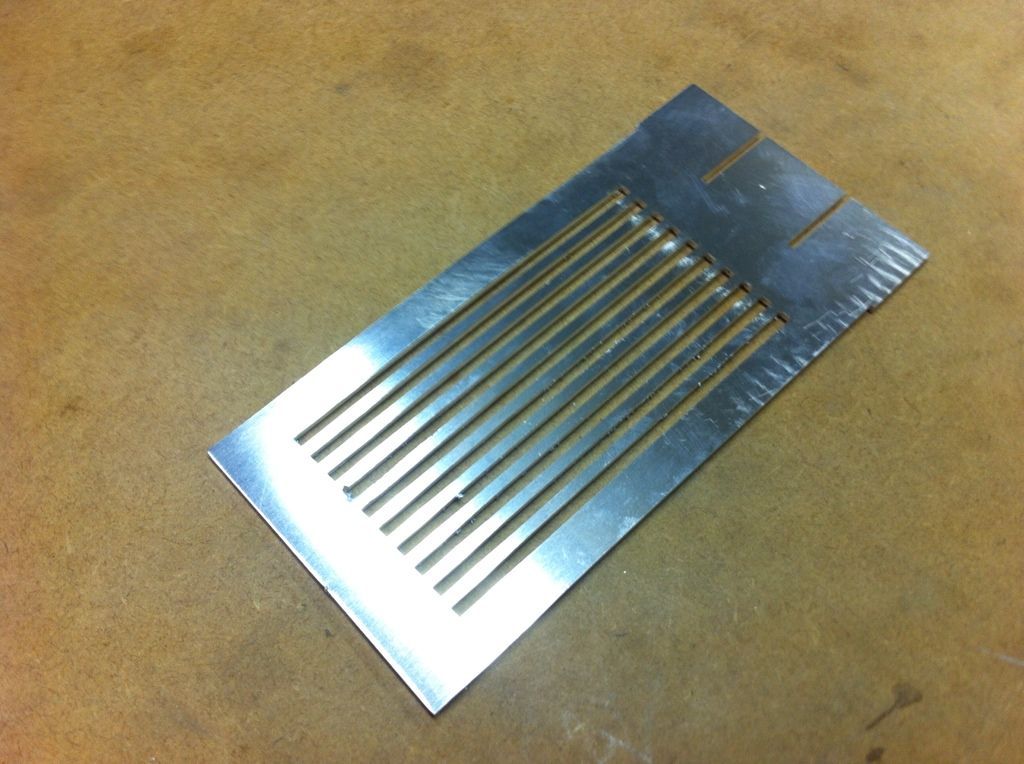

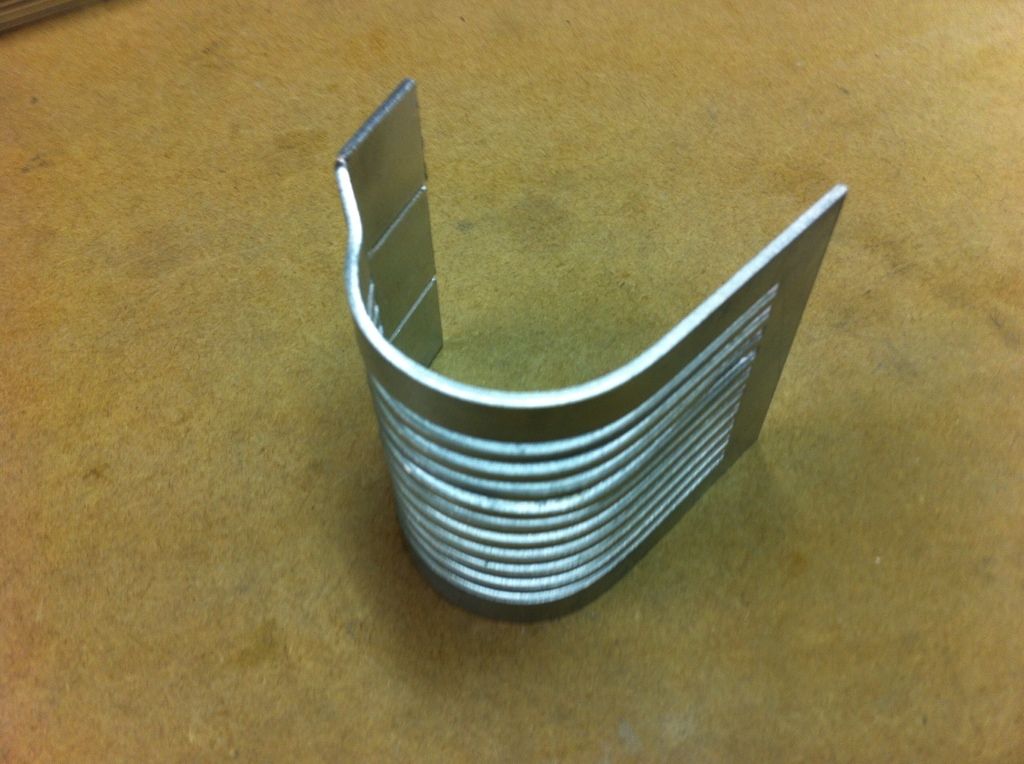

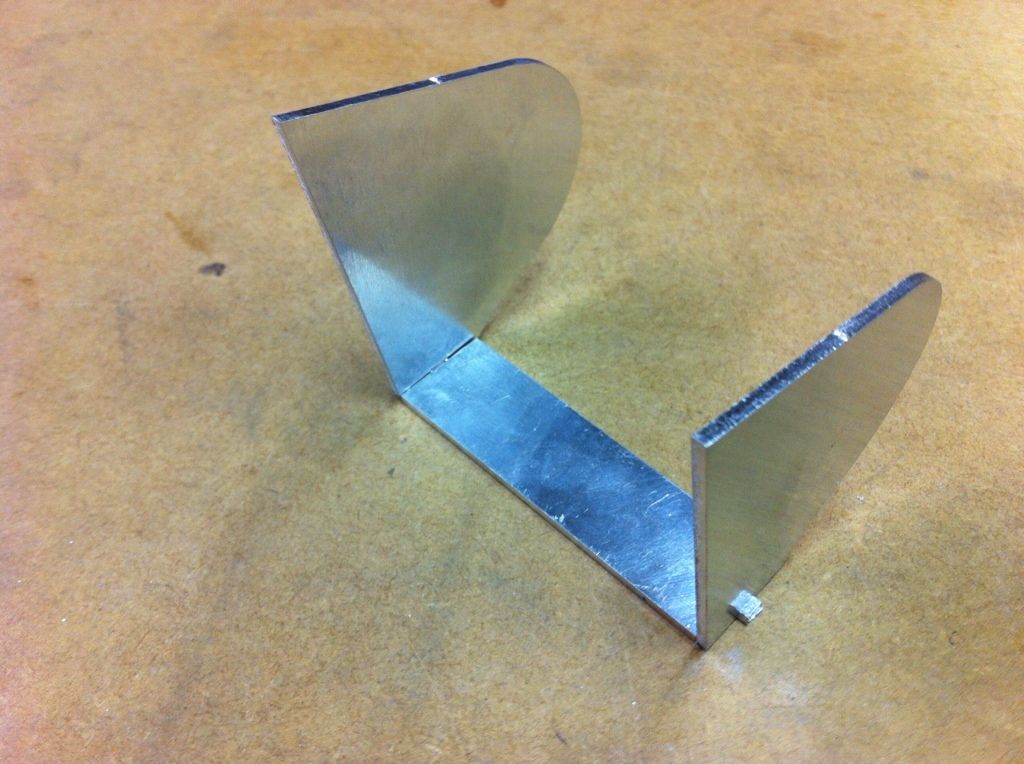

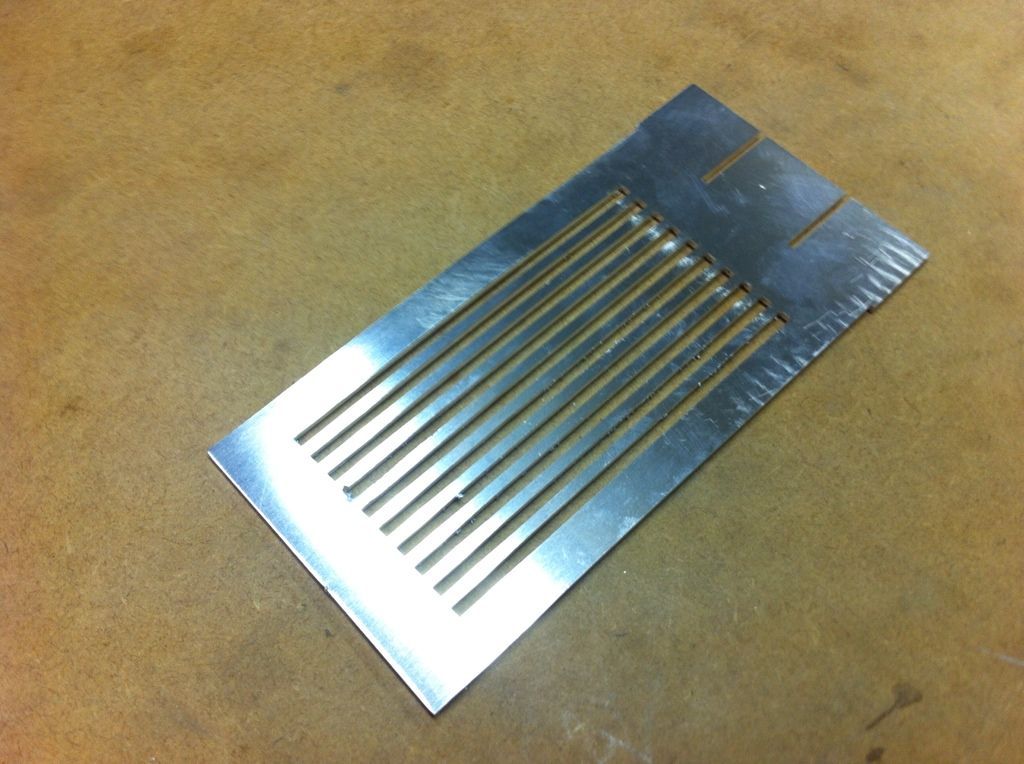

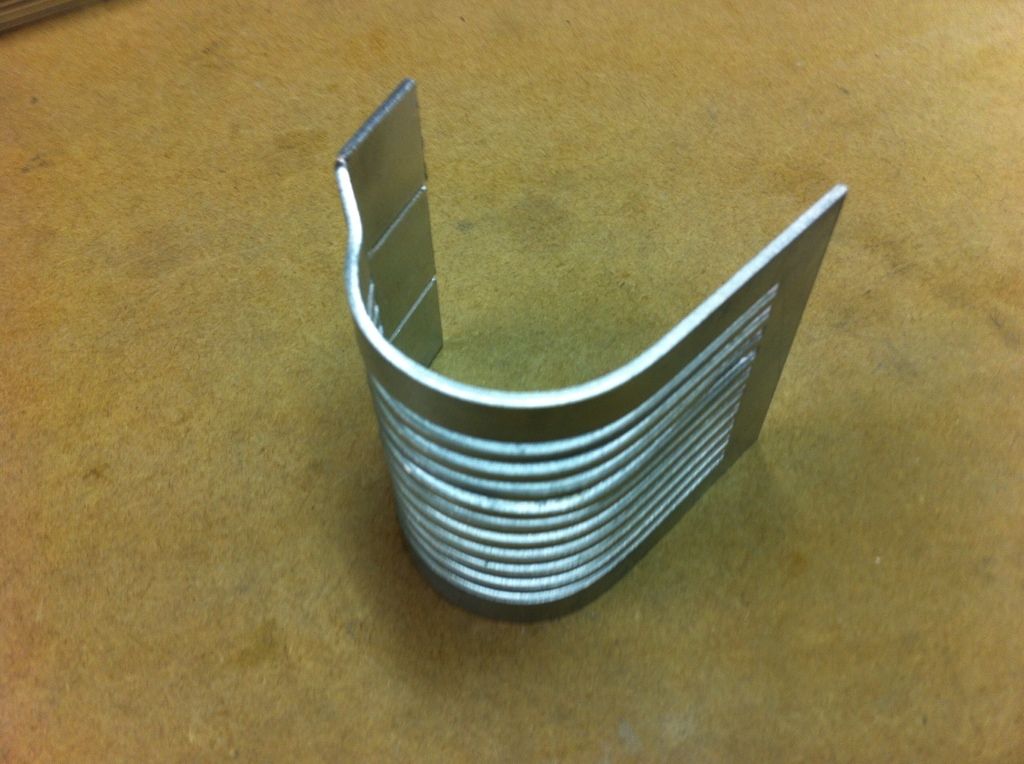

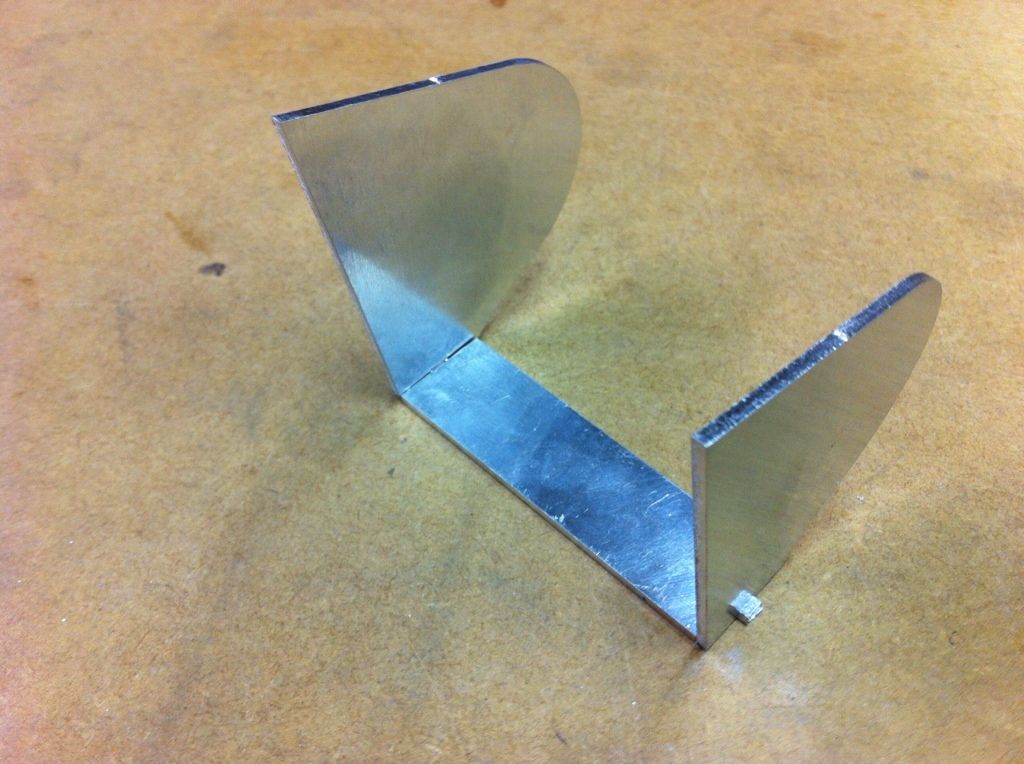

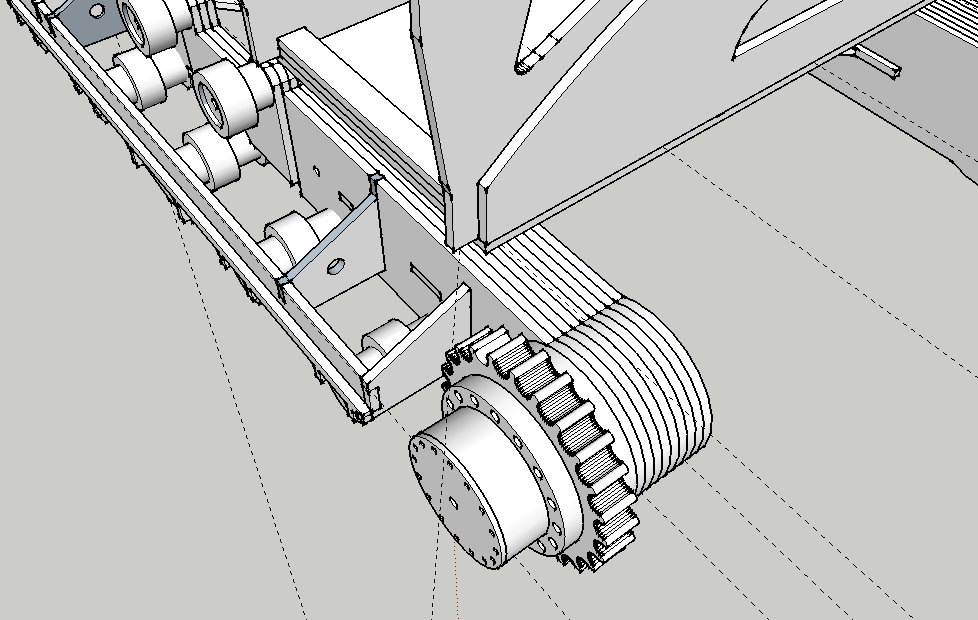

I have added a new item in my design!!

a dirt/rock separator bucket. The backplate is now available for anyone who wants it in their kit.

a few pictures below:

what do you think about it??

Geschrieben von Kette1zu8 am 04.10.2012 um 19:20:

good job!

Geschrieben von Sandokahn am 04.10.2012 um 19:58:

indeed ...

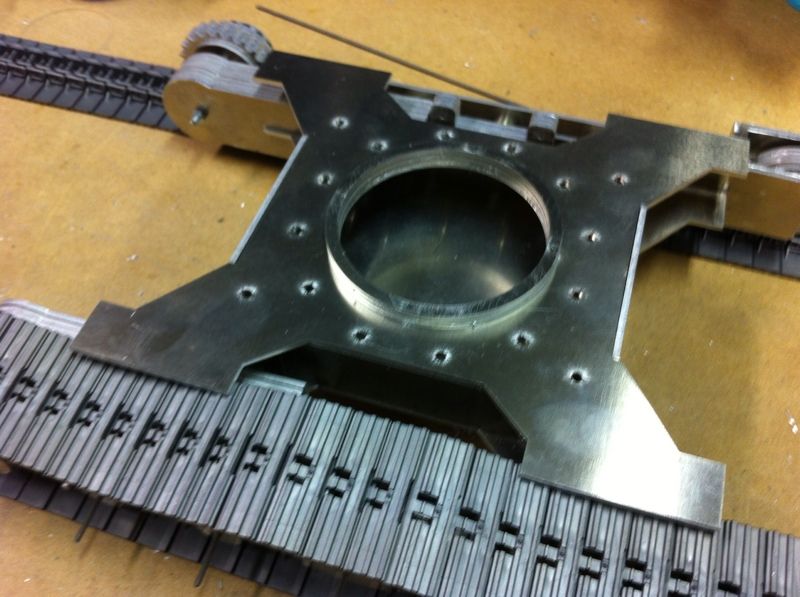

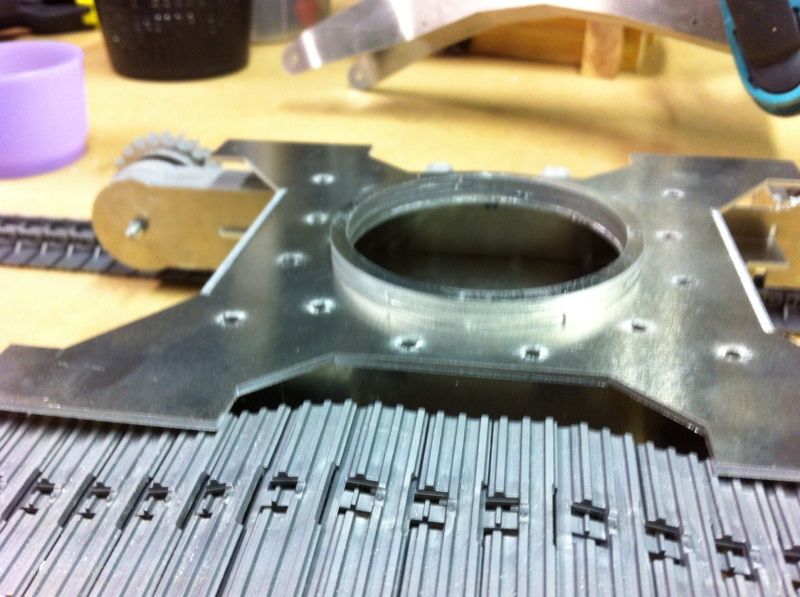

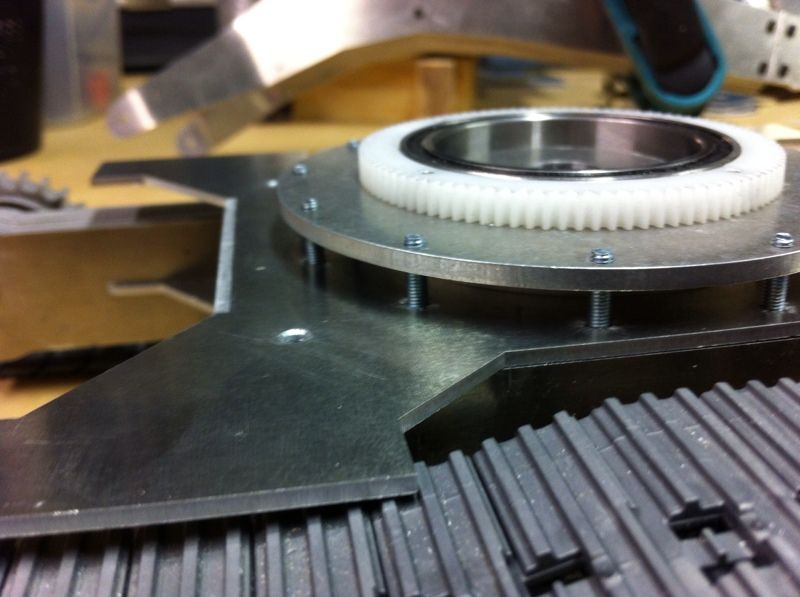

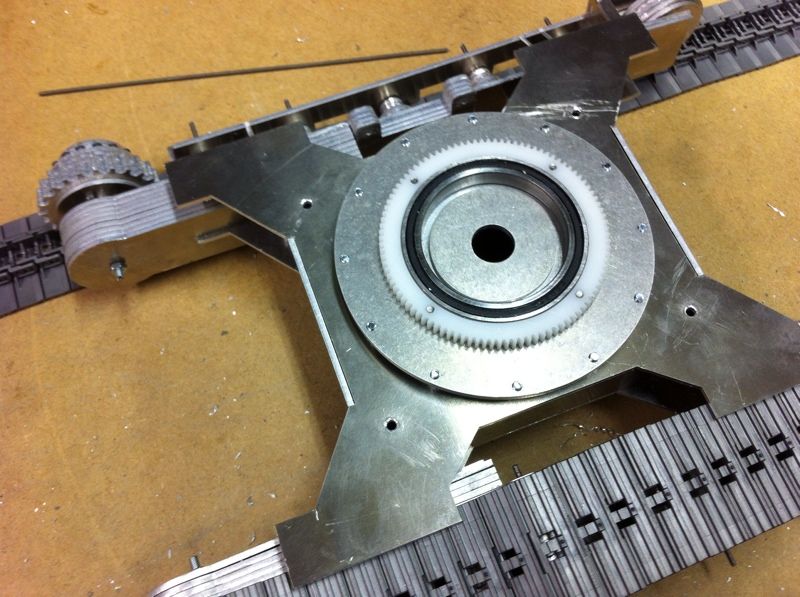

Geschrieben von caterpilar am 08.10.2012 um 20:52:

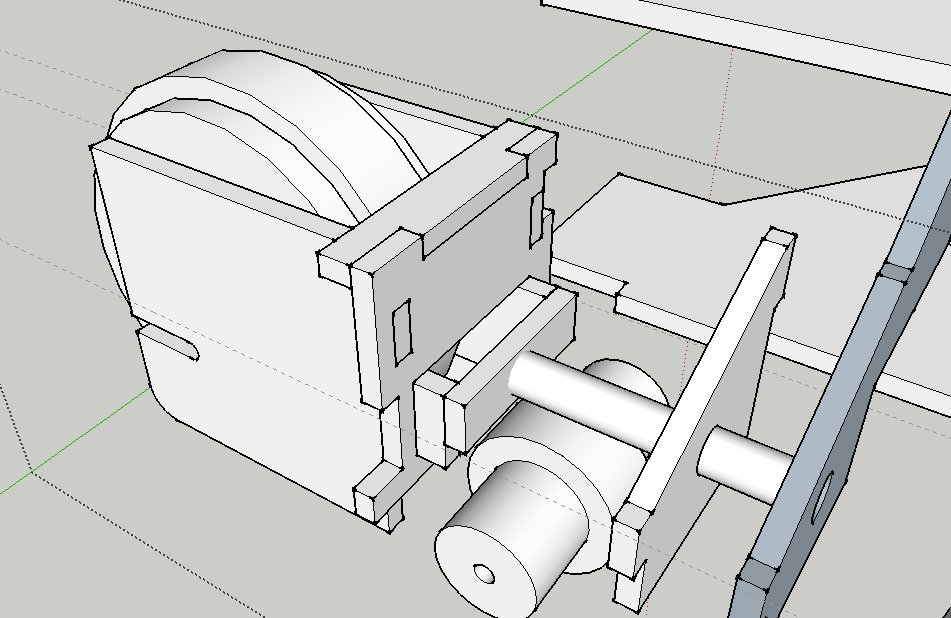

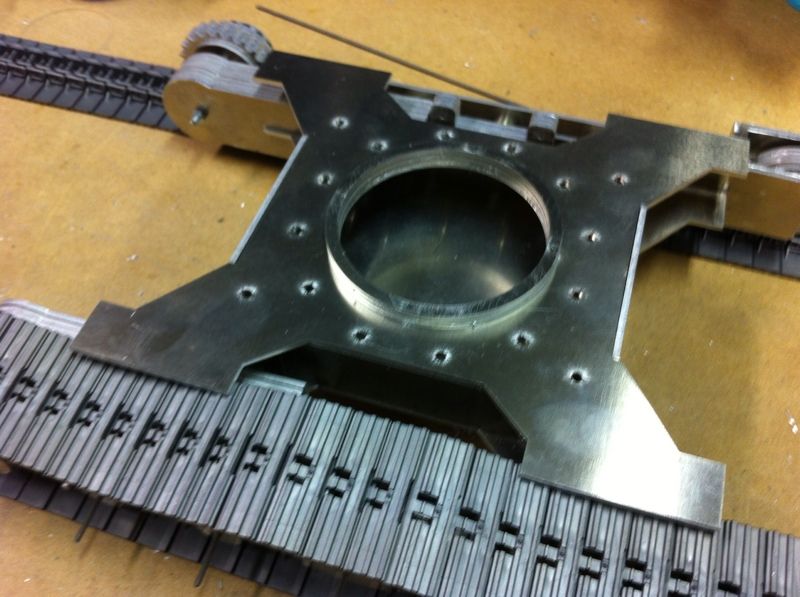

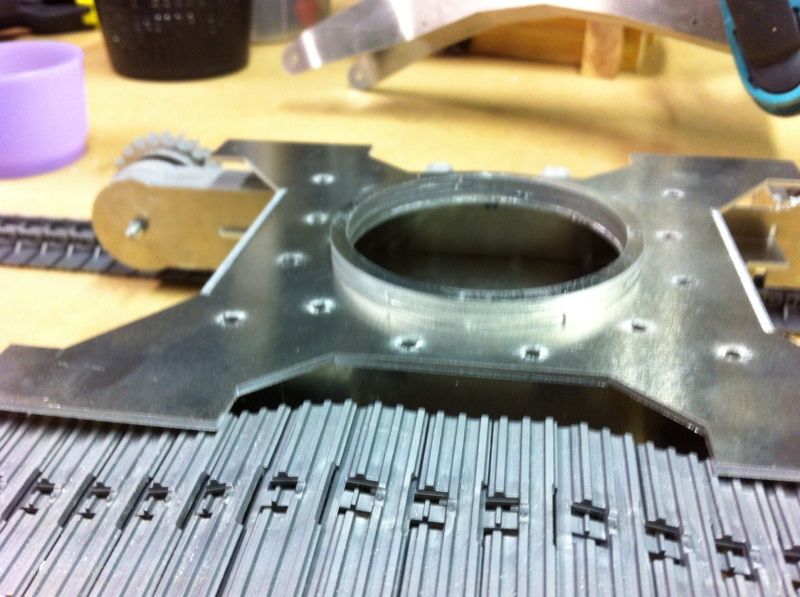

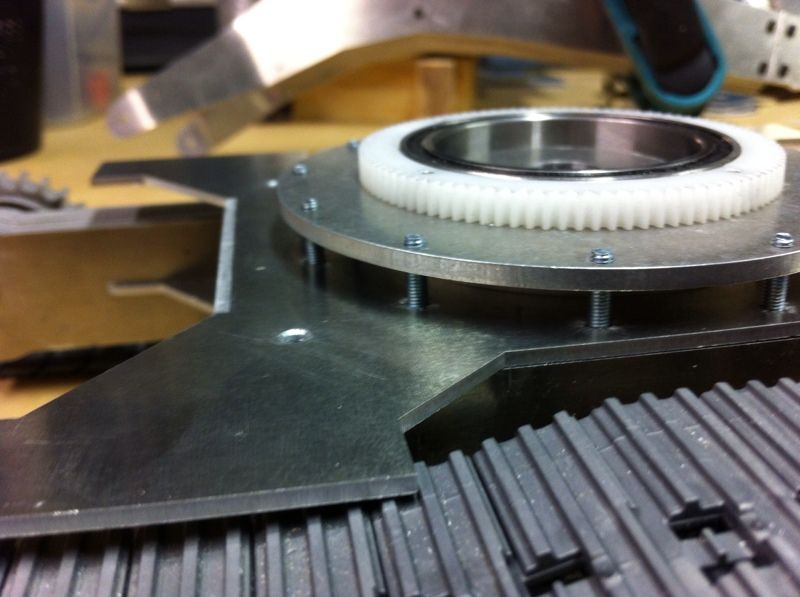

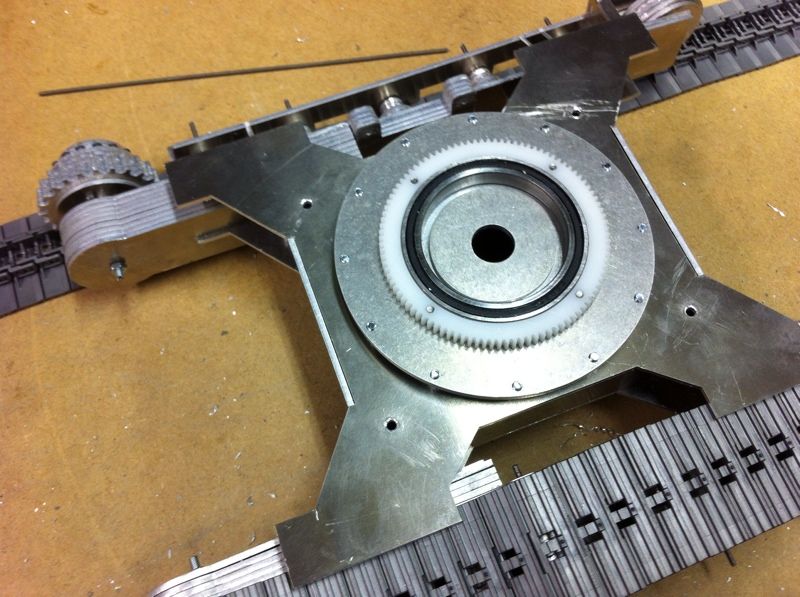

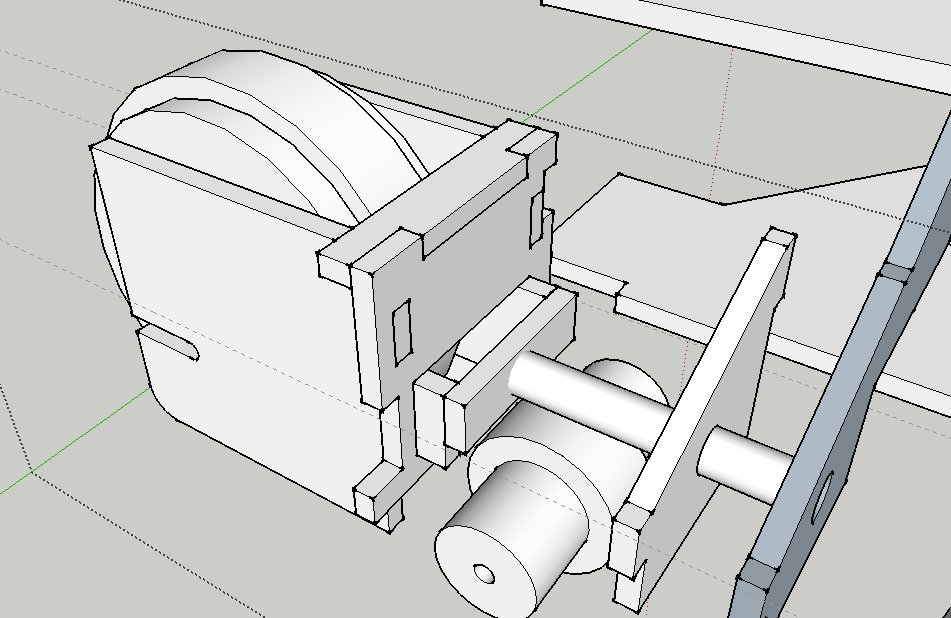

Drehkranz heute in mailbox

it fits perfectly with the model

Geschrieben von caterpilar am 11.10.2012 um 17:28:

I have checked the hydraulics and I will be getting cylinders from Robbe and the other Hydraulic components from Leimbach.

Geschrieben von caterpilar am 07.11.2012 um 10:50:

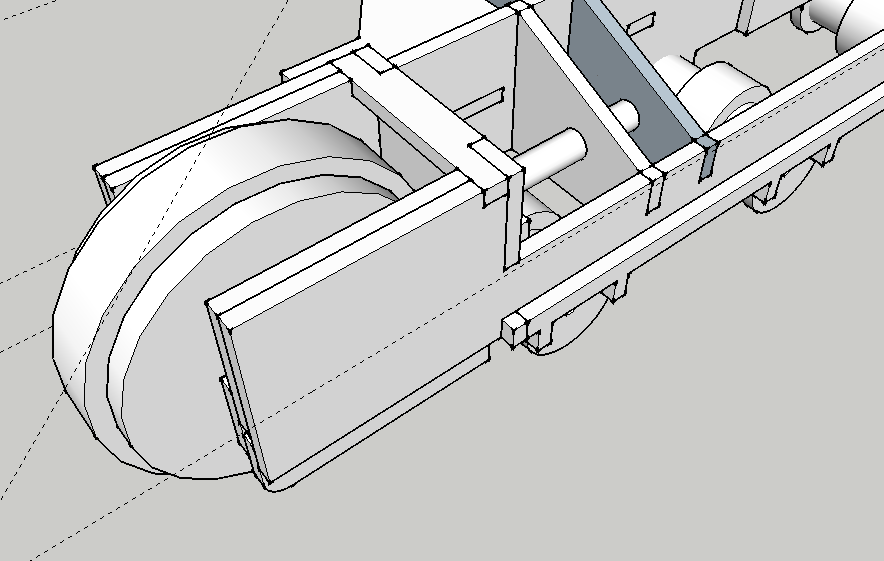

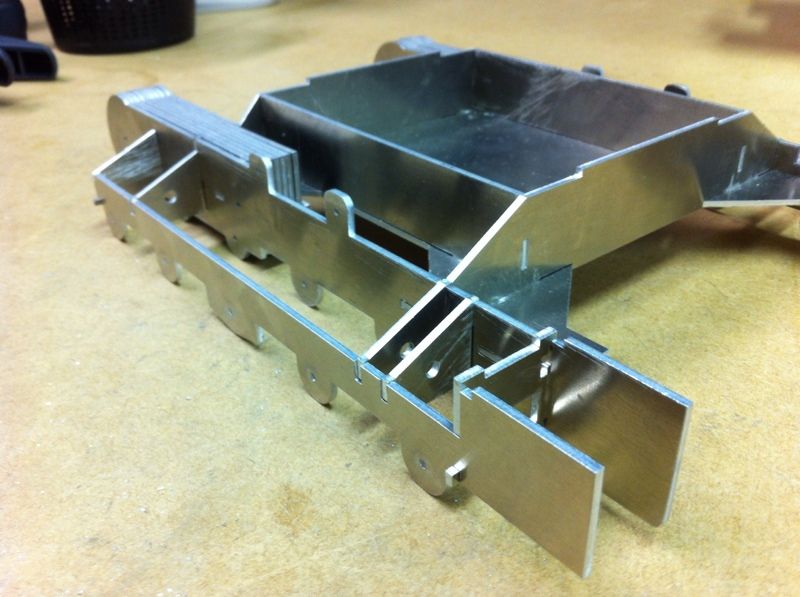

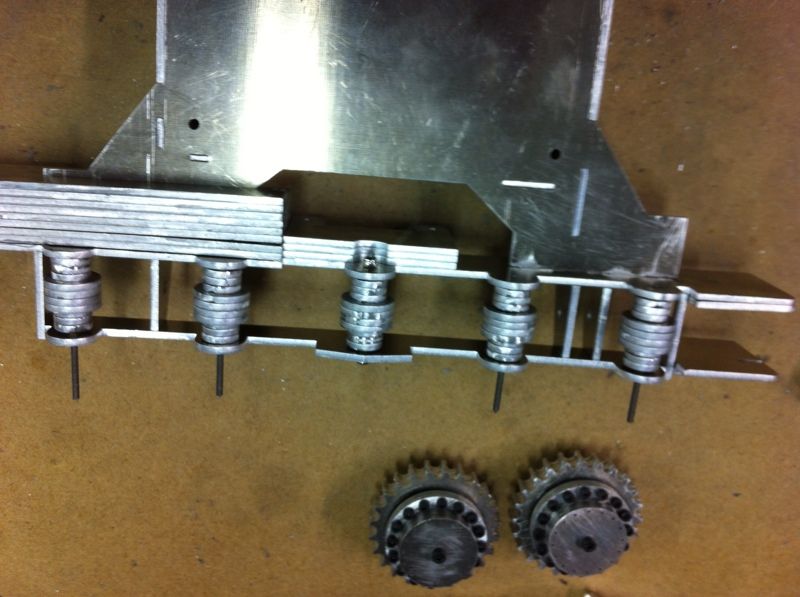

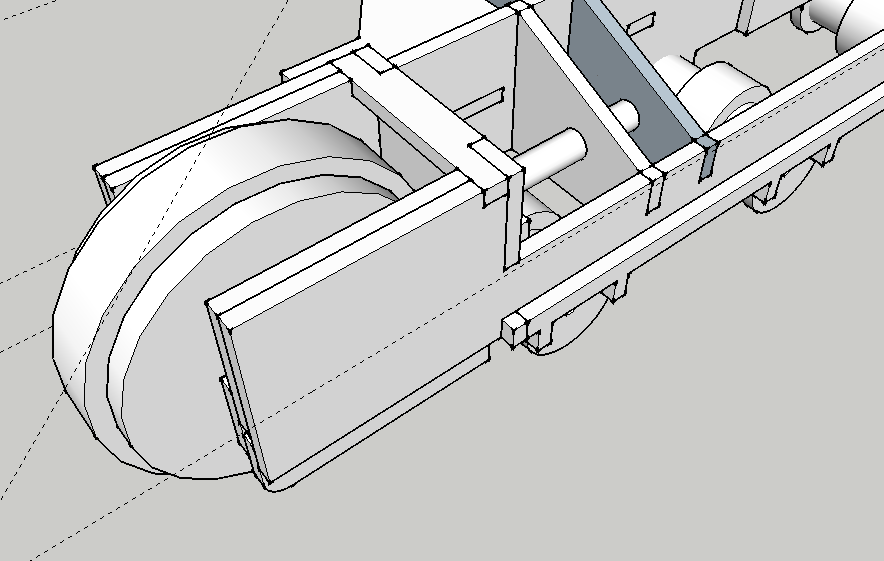

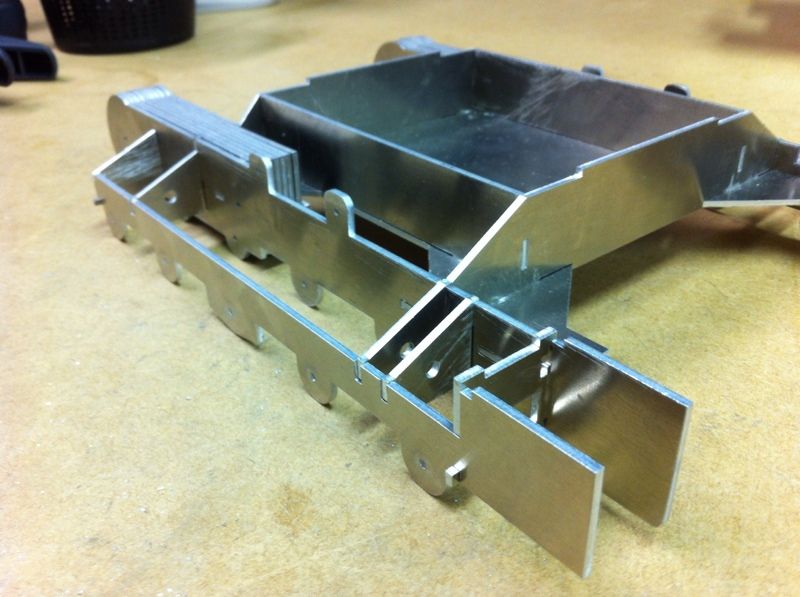

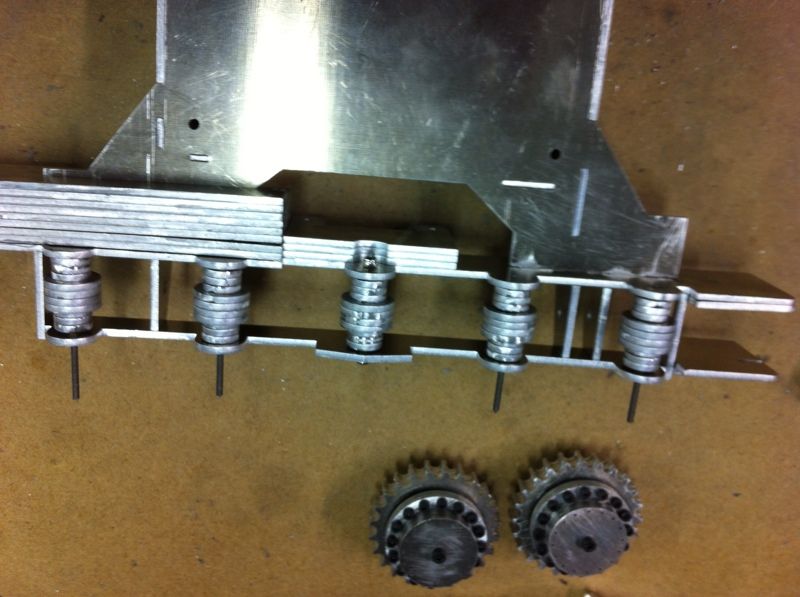

und jetzt den unterwagen.

Geschrieben von caterpilar am 12.11.2012 um 11:33:

Geschrieben von caterpilar am 12.11.2012 um 13:21:

Geschrieben von caterpilar am 13.11.2012 um 17:38:

Geschrieben von caterpilar am 14.11.2012 um 19:11:

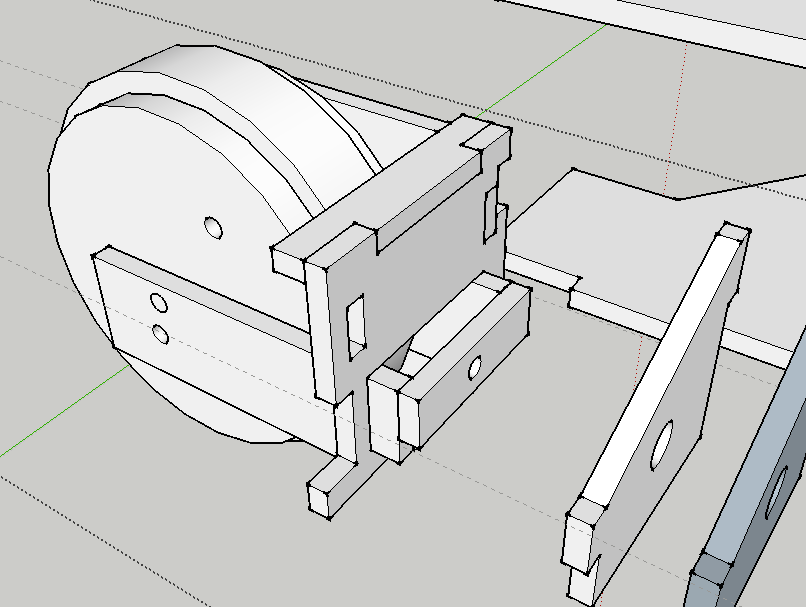

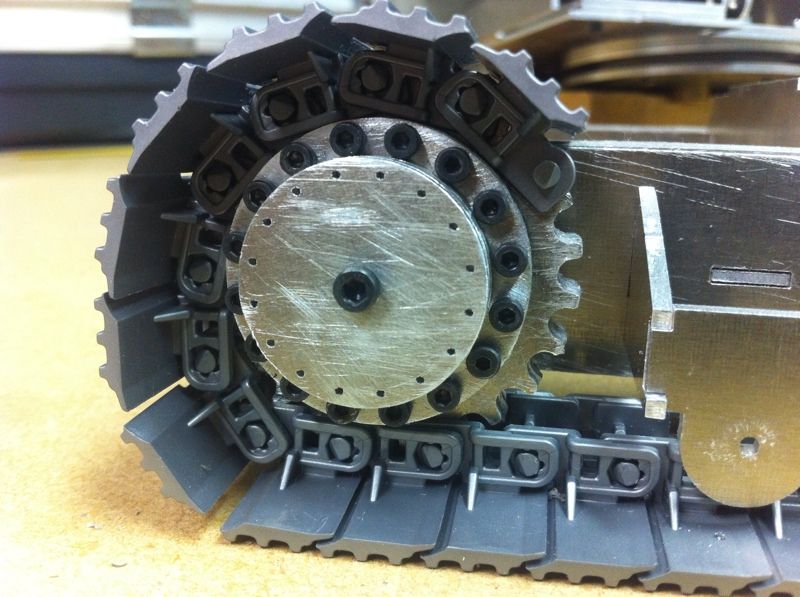

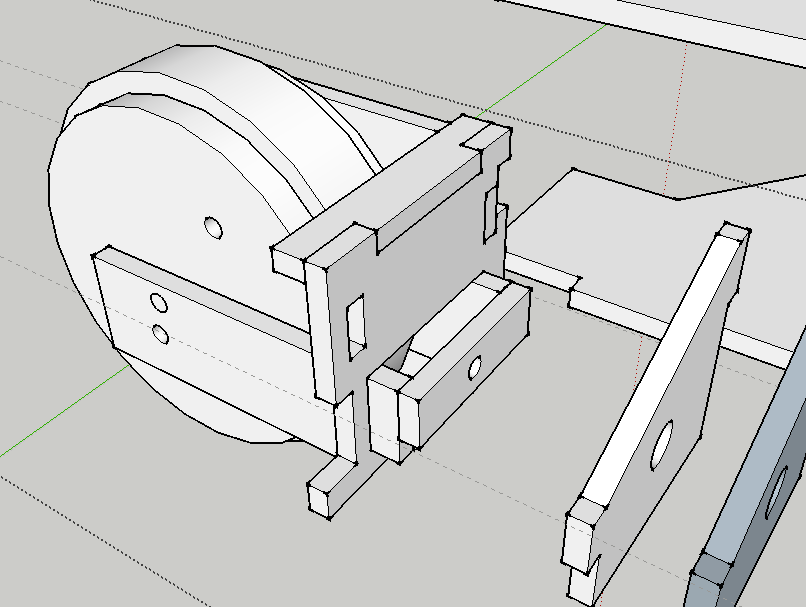

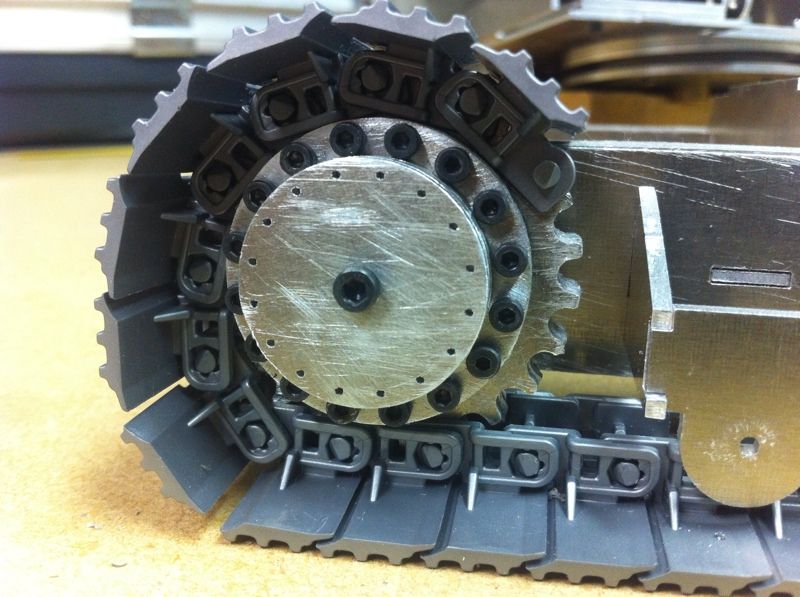

today I put together the sprocket wheel.

I used the following items in addition to the alu cut wheels:

- piece of M2 threaded rod

- M2,5 bolt 8mm long

- M6 to 4mm part to connect the sprocket wheel to the motor

- M2 nut

detail of the connection piece

with a 6mm drill bit I started to make the holes bigger

then i used a 5,5mm drill bit to make the other holes bigger. I used a M6 steel bolt to thread the 5,5mm holes of the round plates so they would fit on the connection piece

then i drilled a 2mm hole in the middle of the connection piece so I could fit the M2,5 bolt in it to hold the last 3 round plates

thats how the front looks

the back side, after cutting of the excess of the M2 rod and adding the nut.

i decided to add 16 bolts M2 of 6mm to finish off the front

still 13 bolts to go

Geschrieben von caterpilar am 15.11.2012 um 09:36:

Geschrieben von caterpilar am 16.11.2012 um 17:38:

Geschrieben von caterpilar am 16.11.2012 um 17:49:

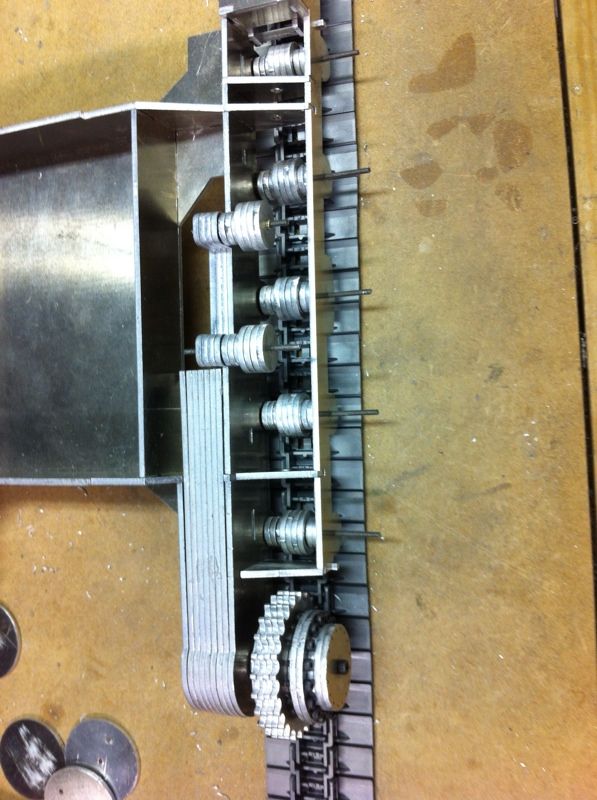

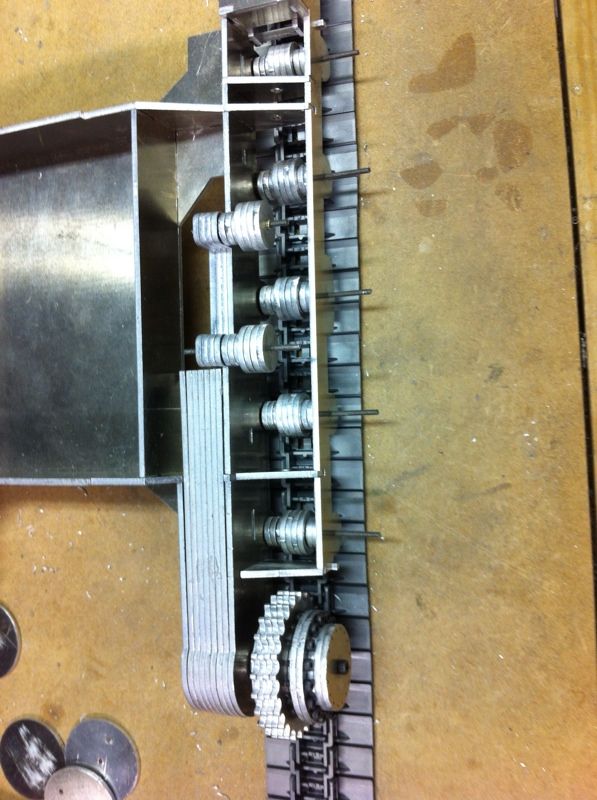

first (short) video of the undercarriage. Still work in progress but happy about the result so far.

http://www.youtube.com/watch?v=1WBFo-rpPOs

Currently using the bruder plastic tracks just as a test while waiting for the delivery of the final tracks.

Geschrieben von caterpilar am 18.11.2012 um 19:31:

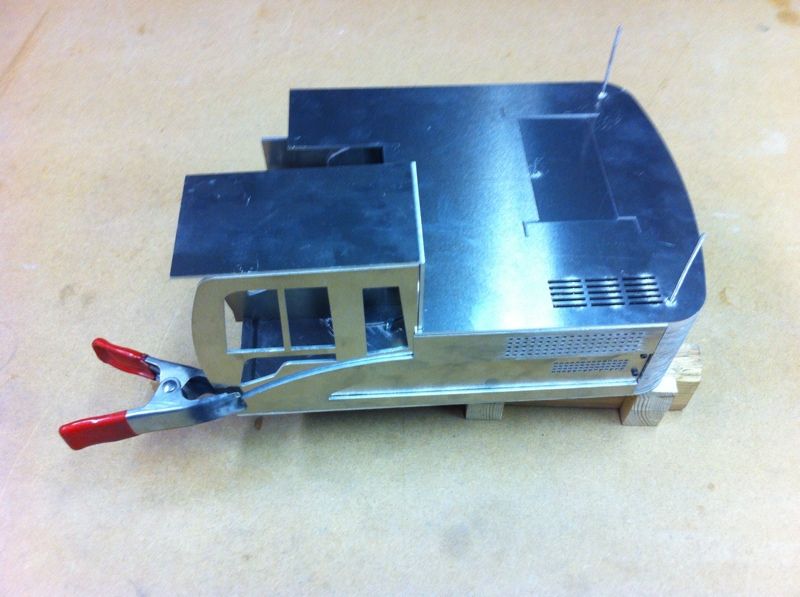

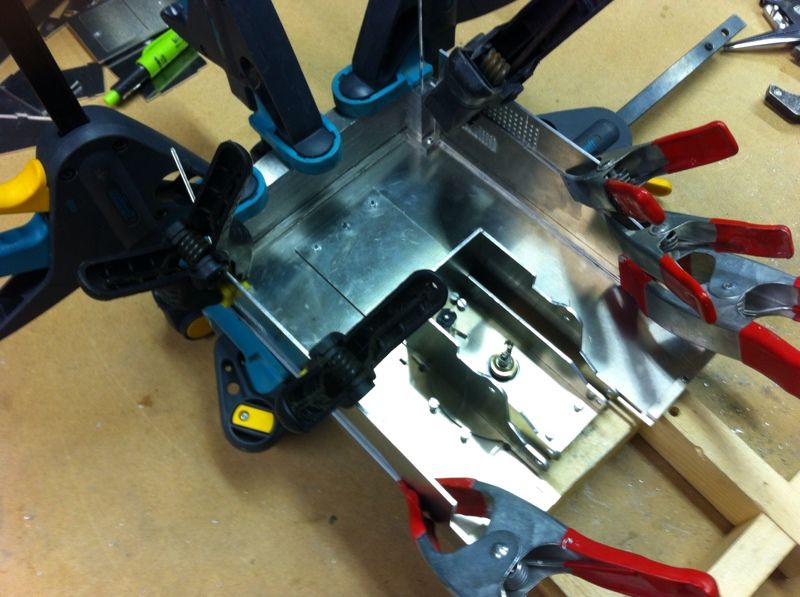

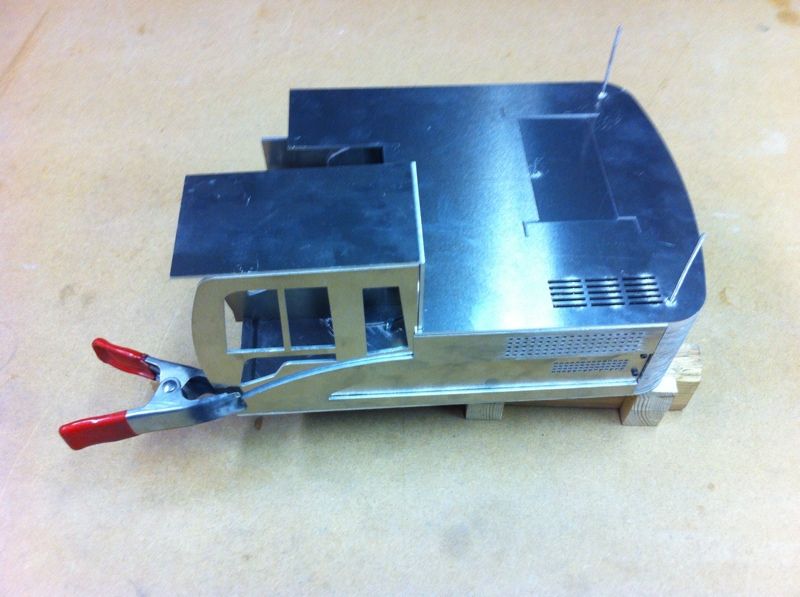

Today i did the brazing of the cabin with Alu flux rods. Here a few pics. Enjoy!

All brazing done with Easyweld de Durafix. It worked really well and the result is nice.

I am using a normal torch to heat up the aluminum.

1. Very important is to clean the place which you want to de brazing on with the copper brush

2. heat up the aluminum till its hot (i mean really HOT)

3. only then come carefully in with the aluminum flux rods from easyweld. if you come in too early, they will melt and bulb up with an ugly result.

4. slightly rub with the flux rods on the hot aluminum and you will see it melts nice and evenly while you pull the rods over the hot surface.

Here a "walk through video of the cabin".

http://www.youtube.com/watch?v=toIhM_AYci4

Geschrieben von Baggerkalle am 19.11.2012 um 12:27:

Kenne ich Alu lötten haben wir auch mal gemacht , auf der Messe gekauft . Super Top . haben wir gedacht nach einem jahr sind die Teile auseinander Gefallen .

Gruß Kalle

Geschrieben von caterpilar am 19.11.2012 um 13:57:

mit Durafix fält es nicht auseinander

Schön grundig getestet

Forensoftware: Burning Board 2.3.6, entwickelt von WoltLab GmbH

mit Durafix fält es nicht auseinander

mit Durafix fält es nicht auseinander  Schön grundig getestet

Schön grundig getestet